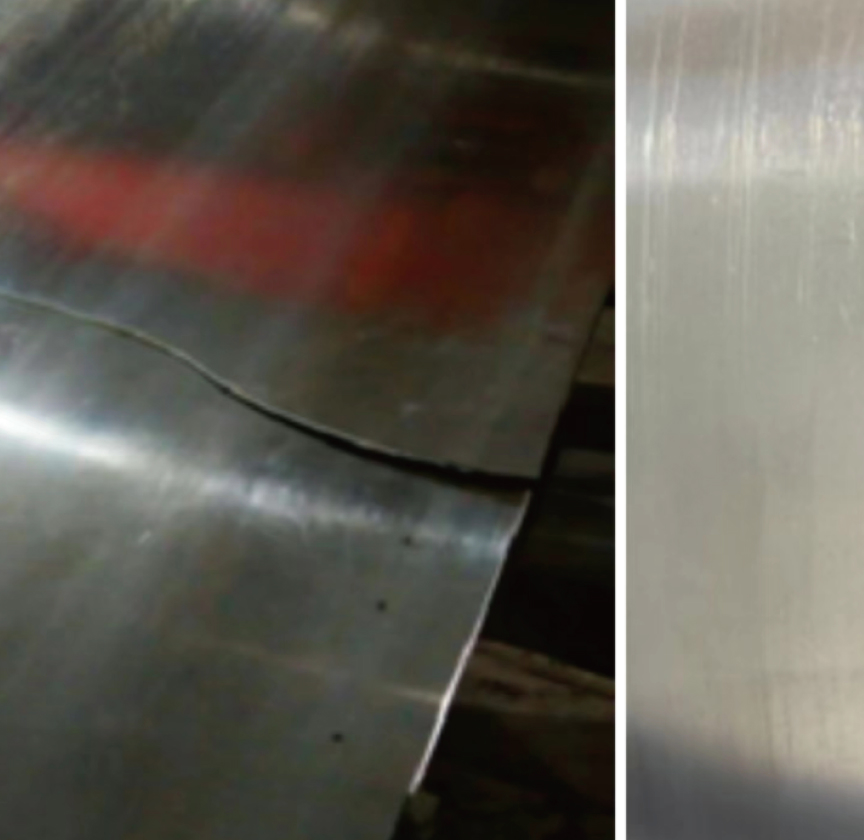

We can provide high-precision cross welding for high-strength precision steel belts. The weld strength matches the base material, meeting the stringent usage requirements of industrial scenarios.

Rapid patching is a highly efficient process for repairing local damage. It achieves fast and seamless restoration by precisely removing the defective part and filling it with matching repair materials.

It is a classic sealing and reinforcement process for designated positions on both side edges of steel belts. During operation, cracks are first cleaned into V-shaped grooves, and then special adhesive is filled in and rubber strips are embedded to make them flush with the surface.

It is a surface strengthening technology that creates a compressive stress layer on the workpiece surface by impacting it with a high-speed projectile stream. This method can significantly improve the fatigue strength and corrosion resistance of metal part, and extend its service life.

It is a systematic treatment solution for surface cracks in materials and structures. The core lies in accurately judging the nature of cracks and adopting processes such as sealing, injection and reinforcement. This not only restores the integrity of the appearance, but also aims to eliminate potential dangers, restore and enhance the load-bearing capacity and durability of the structure.

Our technicians have accumulated a great deal of practical experience and are familiar with the operation characteristics of various steel belt equipment. When facing maintenance needs, they can promptly and accurately identify problems and carry out operations rapidly, helping your equipment resume production quickly.

With our service network covering the whole country, no matter where your production line is located, our professional service team can respond quickly, rush to the site at the first time, and provide reliable maintenance for the system or related components.

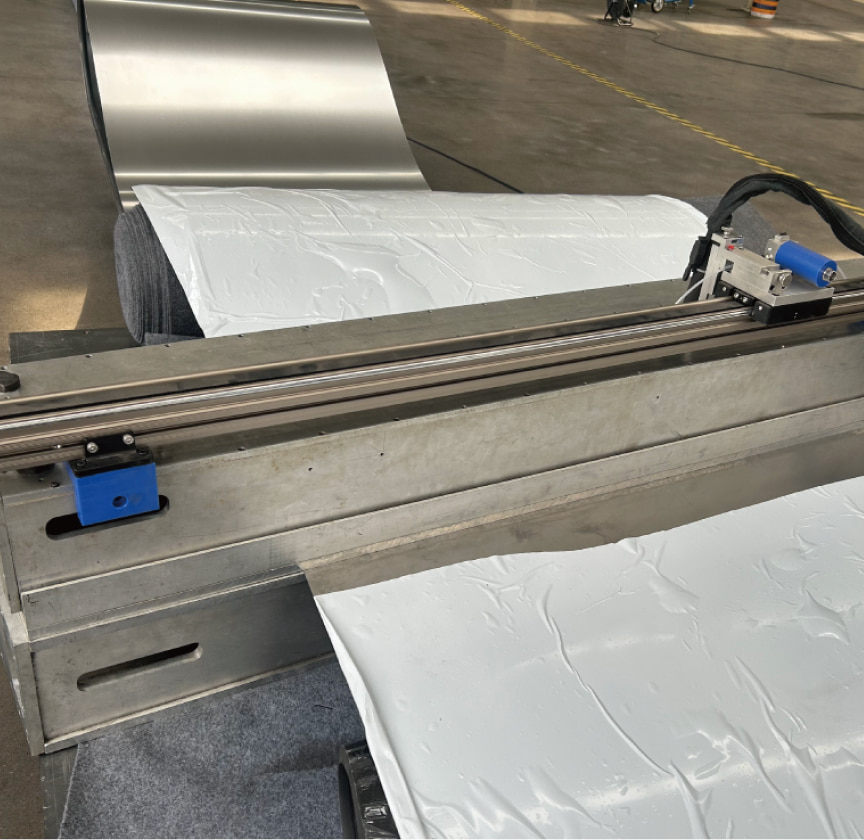

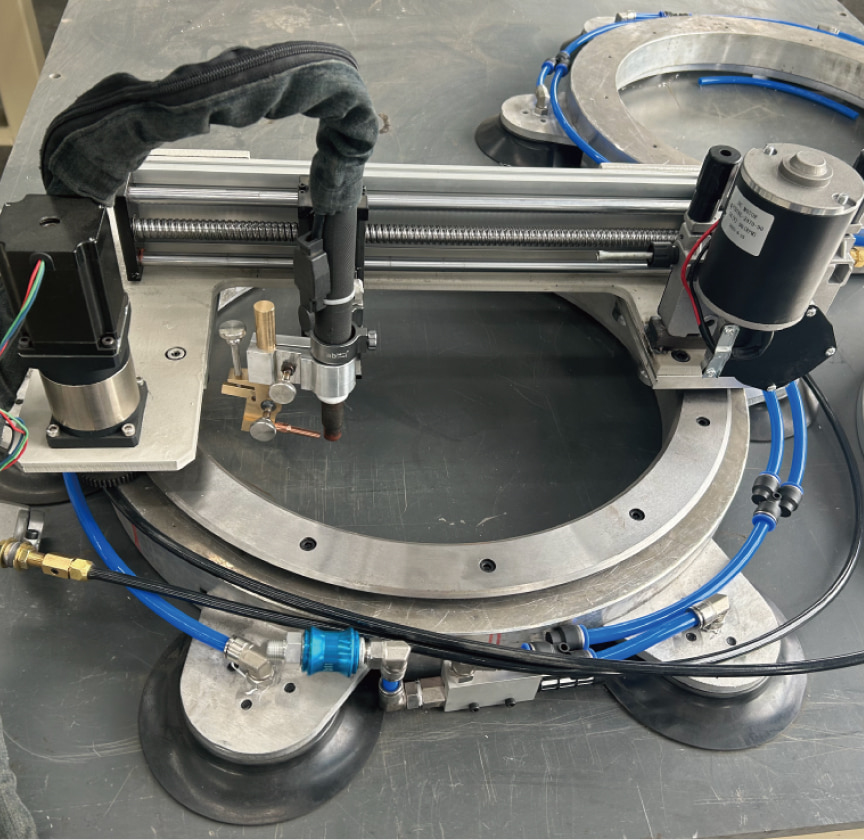

Rebo focuses on innovation and has independently developed a variety of patented service tools. These exclusive tools can effectively improve the accuracy and efficiency of operations during on-site steel belt installation and maintenance for customers.

Our experts will conduct in-depth research on your production scenarios and equipment conditions, and tailor a customized equipment maintenance plan for you. Through scientific planning and meticulous operation, we will minimize equipment downtime to the greatest extent, ensuring the continuous operation of production.

Our service keeps up with the latest technical standards iteration and upgrades. It not only ensures your steel belts always maintain optimal performance, but also helps you optimize production costs throughout the entire process, from technical application to production coordination.

At Rebo, we optimize production processes through innovation. This not only ensures every steel belt strictly meets the highest quality standards, but also enables efficient and timely delivery, providing solid guarantee for your production schedule.

Dedicated to high strength precision steel belt manufacturing, empowering various industries that use steel belts.

Our extensive range of custom steel belt products can enhance the efficiency of your production process.

Widely used in core process links of various manufacturing field