| Length | Width | Thickness |

|---|---|---|

| ≤150 m | 1440~3200 mm | 2.3/2.7/3.0/3.5 mm |

| Length | Width | Thickness |

|---|---|---|

| ≤150 m | 1400~3200 mm | 1.8/2.0 mm |

| Length | Width | Thickness |

|---|---|---|

| ≤150 m | 1400~3200 mm | 1.4/1.5 mm |

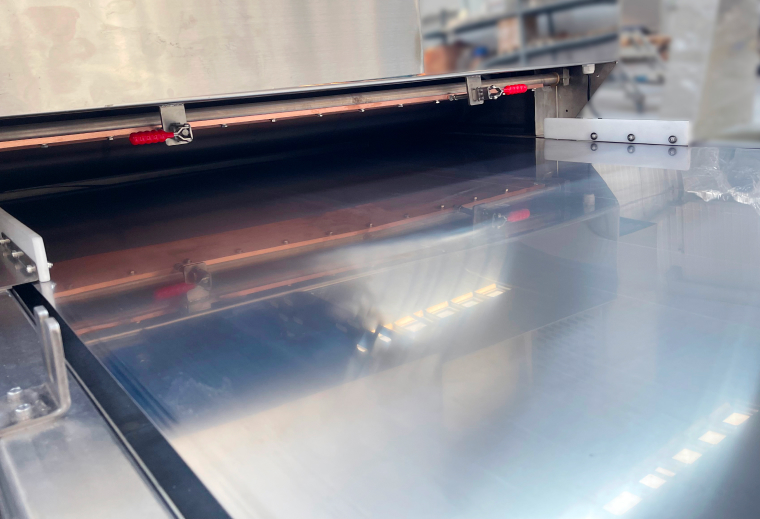

Equipped with modules specifically designed for thermoplastic composites, it accurately matches the processing needs of thermoplastic adhesive layers and composite structures in the wood-based panel industry.

It enables precise control of the polymer cooling curve, providing a stable cooling environment for wood-based panel forming and adhesive layer curing, thus ensuring board performance and flatness.

Withstanding a high pressure of 50 bar, it uniformly transmits pressure during the hot pressing of wood-based panels, guaranteeing uniform density and dense structure of the board.

It supports rapid module replacement without disassembling the steel belt, which can significantly shorten the model changeover time of wood-based panel production lines, and improve production flexibility.

The steel belt features extremely high surface precision. it gives a flatter and smoother surface to wood-based panels during pressing process, reducing appearance defects.

With excellent wear resistance, it exhibits minimal wear when in long-term contact with wood-based panels and adhesives, extending the service life of equipment, reducing maintenance frequency and costs.

It is resistant to corrosive media such as glue and moisture, enabling long-term stable operation in the complex production environment of wood-based panels, reducing the replacement frequency of steel belt.

It can work stably at temperatures up to 420°C, meeting the high-temperature requirements of the hot pressing process for wood-based panels, ensuring continuous and efficient production.

Dedicated to high strength precision steel belt manufacturing, empowering various industries that use steel belts.

Our extensive range of custom steel belt products can enhance the efficiency of your production process.

Rebo offers you professional, prompt, and efficient after-sales service