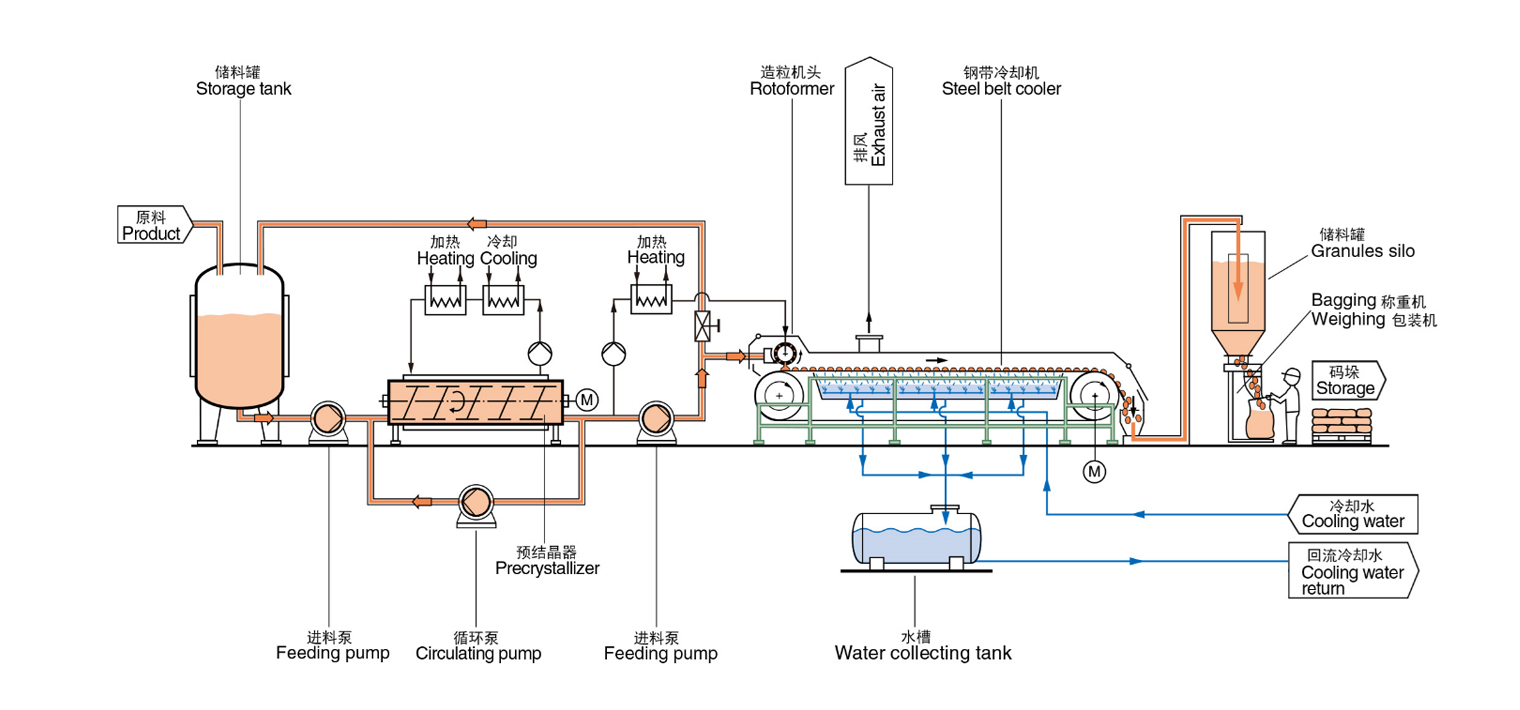

*Thin steel belts with forced spray cooling ensure rapid heat transfer, allowing the molten material to solidify and form quickly.

*Less air contact, less dust, higher efficiency, and a cleaner production environment.

*The product has stable quality, full granules, and good flowability.

*Continuous operation, with high single-machine output; fewer wear parts, and lower operating costs.

| Model | Width Of Steel Belt(mm) | Effective Length(mm) |

|---|---|---|

| RCB1000-L25 | 1000 | 5000-25000 |

| RCB1200-L25 | 1200 | 5000-25000 |

| RCB1500-L25 | 1500 | 5000-25000 |

Dedicated to high strength precision steel belt manufacturing, empowering various industries that use steel belts.

Our extensive range of custom steel belt products can enhance the efficiency of your production process.

Rebo offers you professional, prompt, and efficient after-sales service

All fields marked with an asterisk (*) are required.

The information you provide will only be used for file download and service optimization. We strictly protect your data security.