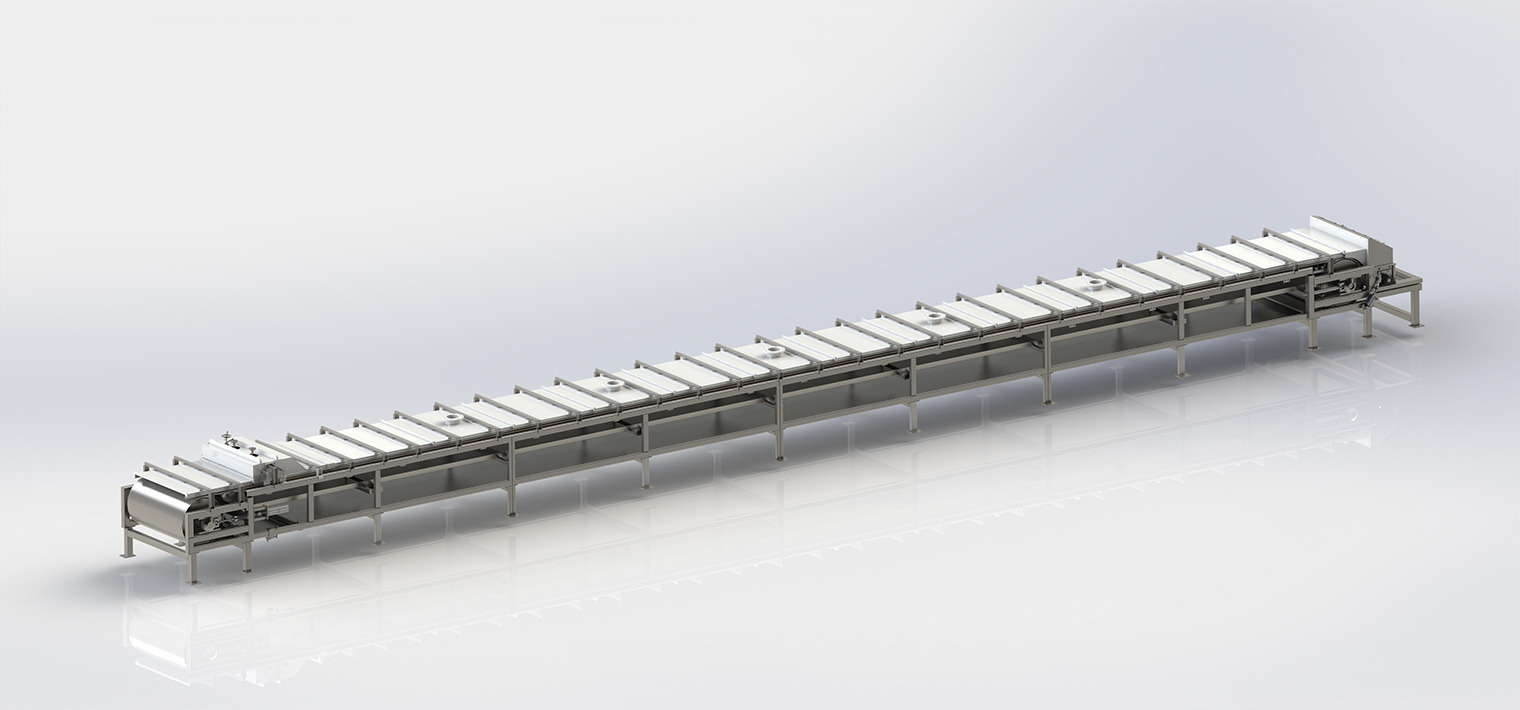

*The material solidifies rapidly, generating minimal dust during crushing.

*Design of overflow spout feeder ensures uniform and consistent product distribution.

*Stable performance and well-designed mechanical structure.

*Production speed could be adjusted or controlled according to material characteristics and production requirements, with multi-stage temperature control.

This product is perfectly suited for the chemical and food processing industries, featuring a compact design that combines excellent cooling performance with highly efficient heat exchange capabilities.

| Model | Width Of Steel Belt(mm) | Effective Length(mm) |

|---|---|---|

| RDB1000-L25 | 1000 | 5000-25000 |

| RDB1200-L25 | 1200 | 5000-25000 |

| RDB1500-L25 | 1500 | 5000-25000 |

Dedicated to high strength precision steel belt manufacturing, empowering various industries that use steel belts.

Our extensive range of custom steel belt products can enhance the efficiency of your production process.

Rebo offers you professional, prompt, and efficient after-sales service

All fields marked with an asterisk (*) are required.

The information you provide will only be used for file download and service optimization. We strictly protect your data security.