May 06, 2024

May 06, 2024  203

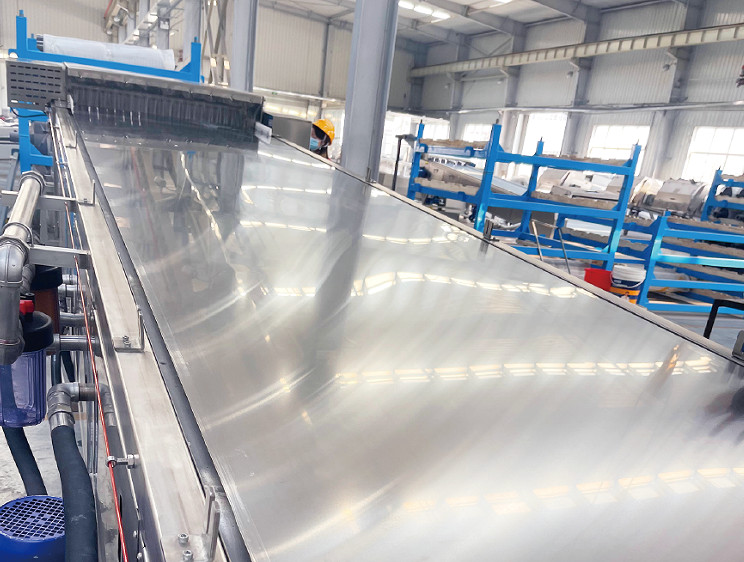

203 In the industrial sector, drive steel belts have become core components of numerous mechanical systems, facilitating efficient and stable automation and production line operations. With their unique properties and advantages, drive steel belts are gradually shaping the new face of modern industry.

The drive belt, crafted from high-strength and wear-resistant special steel, combines flexibility and durability. It is the inherent properties of this material that endow the drive belt with the ability to maintain stability even in high-load and high-speed operating environments, thereby ensuring its long service life. Its meticulous design not only enhances transmission efficiency but also guarantees transmission accuracy, further bolstering the reliability of the overall mechanical system.

In modern industry, steel drive belts are widely used in various mechanical transmission systems, such as logistics conveyors, precision machine tools, and automated production lines. In these systems, they function like blood vessels in the human body, continuously transmitting power and connecting various key components, ensuring the smooth progress of every production step.

It is worth mentioning that the advantages of the transmission steel belt are not only reflected in its physical properties. Its precise transmission ratio and excellent operational stability enable the mechanical system to maintain low noise and low vibration during high-speed operation, thereby significantly improving the overall operational efficiency and stability of the machinery.

However, any mechanical component is bound to encounter issues during use, and the drive belt is no exception. Potential risks such as wear and tear, breakage, etc., are often closely related to material quality, usage environment, and maintenance conditions. Therefore, when selecting and using drive belts, it is necessary to comprehensively consider their various performance parameters and usage environment to ensure their safe and stable operation.

The development of technology has driven industrial progress, and the design and manufacturing technology of drive belts have been continuously innovated in this process. The new generation of drive belts, while maintaining their original advantages, has further improved their strength and wear resistance, and has also achieved significant breakthroughs in transmission efficiency and precision. These technological innovations undoubtedly open up broader prospects for the application of drive belts in the field of industrial automation.

Looking ahead, as the core link for efficient industrial operation, the status of drive steel belts will become increasingly important. Through continuous technological innovation and quality improvement, drive steel belts will continue to lead industrial development and become an indispensable force in promoting industrial automation and efficient operation of production lines.

Dedicated to high strength precision steel belt manufacturing, empowering various industries that use steel belts.

Our extensive range of custom steel belt products can enhance the efficiency of your production process.

Rebo offers you professional, prompt, and efficient after-sales service